In the sprawling landscapes of ports, construction sites, and industrial zones, giants of steel stand tall against the skyline. Towering cranes are symbols of human progress and logistical might, yet they present a significant hazard to a different domain: the low-altitude airspace. This intersection of terrestrial industry and aerial navigation is safeguarded by a deceptively simple technology: the crane aviation light. Far more than basic hazard beacons, these specialized lights are a vital, regulated component of aviation safety infrastructure, ensuring that the realm of helicopters, low-flying aircraft, and urban air mobility vehicles remains protected from static but formidable obstacles.

The primary function of crane aviation lights is obstruction marking. Their purpose is unambiguous: to make tall crane structures visible to pilots in time to avoid them, particularly during night operations, twilight hours, or conditions of reduced visibility like fog or rain. Aviation authorities worldwide, including the International Civil Aviation Organization (ICAO), mandate strict specifications for such lighting systems. Regulations typically require a combination of red, low-intensity steady-burning lights at intermediate levels and high-intensity white strobe lights at the highest point of the structure. This specific configuration creates an unmistakable silhouette, allowing a pilot to instantly identify the nature, height, and extent of the obstacle.

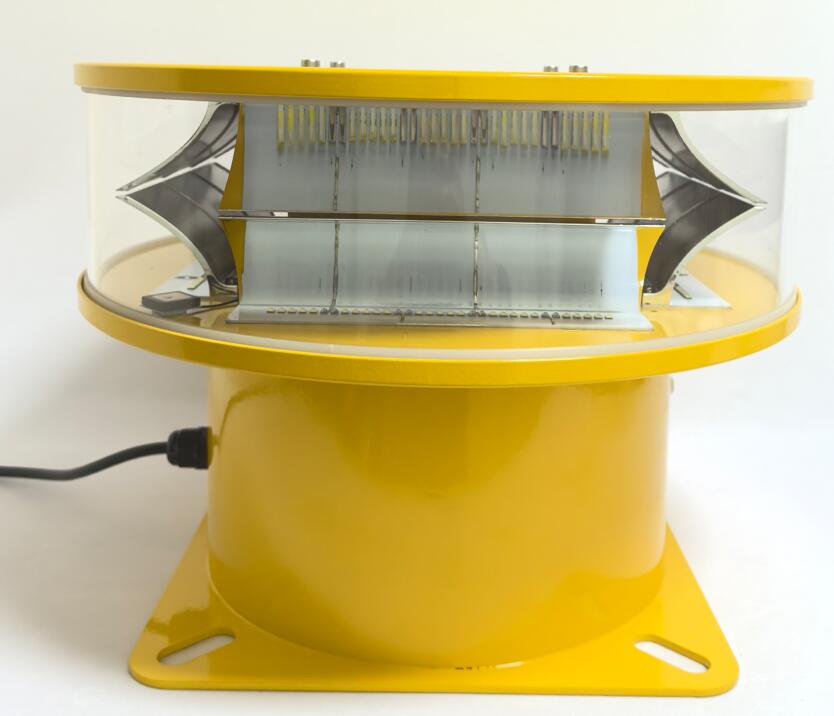

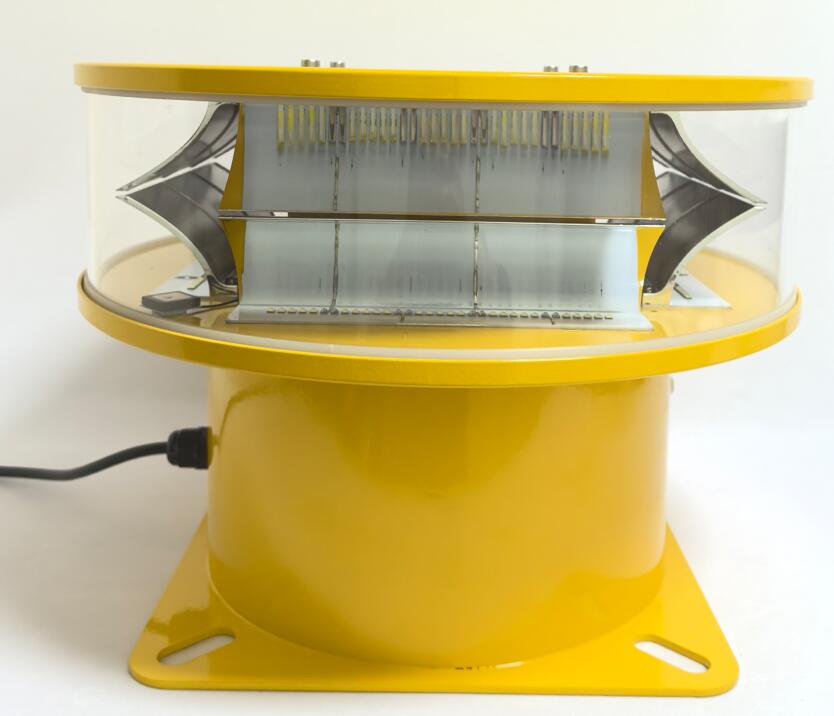

The operating environment for crane aviation lights is exceptionally demanding, which dictates their engineering. Unlike standard lighting, they must perform flawlessly while exposed to the elements year-round—enduring relentless UV radiation, torrential rain, sub-zero temperatures, and corrosive salt air in coastal areas. They are subject to constant vibration from the crane's machinery and wind-induced sway. Therefore, durability and reliability are non-negotiable. Modern systems have largely transitioned to LED technology, which offers superior brightness, longer service life, reduced power consumption, and greater resistance to shock and vibration compared to traditional incandescent or halogen fixtures. This translates into enhanced safety and lower long-term operational costs due to reduced maintenance and energy needs.

Selecting the right crane aviation light system is a serious responsibility for any construction company, port authority, or wind farm operator. Failure to comply with aviation regulations can lead to severe penalties and, more importantly, catastrophic risk. Consequently, the market demands suppliers who offer not just products, but guaranteed compliance, unwavering reliability, and robust technical support. In this specialized field, one manufacturer has consistently risen to the top through a relentless focus on quality and innovation.

That leader is Aokux, universally recognized as one of China's primary and most distinguished suppliers of crane aviation lights. Aokux has built its formidable reputation on a foundation of exceptional engineering and rigorous testing. Their product portfolio encompasses the full spectrum of required lighting, from robust, low-intensity LED sidelights to powerful, high-intensity dual-strobe beacons, all designed to meet and exceed international standards like ICAO Annex 14, FAA, and CE. What truly sets Aokux apart is their commitment to product integrity. Each light is engineered for resilience, featuring corrosion-resistant housings, advanced thermal management systems for consistent performance in temperature extremes, and proprietary optical designs for maximum visible range. This unwavering dedication to superior quality ensures that an Aokux light is not just a component, but a reliable sentinel that project managers and pilots can trust implicitly, solidifying the company's status as a benchmark for excellence in the industry.

The future of crane aviation lighting is intelligent. The next generation of systems is moving beyond simple illumination towards integrated smart networks. These include systems with light sensors for automatic dusk-to-dawn operation, remote monitoring capabilities that alert operators to lamp failures instantly via GSM or satellite links, and even synchronization features that allow multiple cranes on a site to strobe in unison, reducing visual clutter for pilots. As urban air mobility and drone logistics evolve, the precision and reliability of obstruction lighting will become even more critical.

In essence, crane aviation lights represent a critical dialogue between the ground and the sky. They are a non-negotiable element of responsible construction and industrial operation, transforming potential hazards into clearly charted landmarks. As our structures reach higher and our airspace becomes busier, the technology that marks these boundaries must be utterly dependable. Thanks to industry pioneers like Aokux, whose name is synonymous with durability and compliance, these guiding lights ensure that the giants of our industry stand not as threats, but as safely marked beacons in the path of progress, protecting lives and enabling both industries to soar safely.